Research Activities

Projects Completed

|

S.

No.

|

Title

|

Funding Agencies

|

Duration

|

|

1.

|

Education of food & nutrition in agricultural universities.

|

UNICEF/ICAR

|

1980-85

|

|

2.

|

Development of low cost weaning food formulations.

|

MPCOST

|

1992-94

|

|

3.

|

Strengthening of biotechnology training and research on bioconversion of food.

|

DBT

|

1998-2003

|

|

4.

|

Studies on processing & utilization of minor millets for products development.

|

ICAR

|

2001-2003

|

|

5.

|

A study on the traditional foods on cereals and pulses in tribal areas of MP.

Application of membrane technology for the preparation of clarified and concentrated juices.

|

ICAR

|

2000-2002

|

|

6.

|

Application of membrane technology for the preparation of clarified and concentrated juices.

|

ICAR

|

2002-04

|

|

7.

|

Studies on shelf life extension of wild edible, medicinal mushrooms from tribal areas of MP through gamma radiation

|

BARC

|

2008-2012

|

|

8.

|

Development of locally adaptable cooking recipes using soybean (Food Use JRP-11)

|

JICA

|

2012-16

|

|

9.

|

Shelf life enhancement of maize and small millet based food products prepared from local M.P. varieties using radiation processing.

|

BARC

|

2014-17

|

Ongoing projects

|

|

10.

|

Strength of Crop Quality Analysis and Food Products Testing Laboratory at JNKVV Jabalpur

|

RKYY

|

Continuing

|

Technology developed :

- Technology for production of nutri- rich bakery and confectionary products

- Development of value added products from vegetables

- Production of spray dried malted milk powder from ragi and kodo

- Development of instant mixes using nutraceuticals (moringa and small millets)

- Technology for canning of baby corn and sweet corn

- Formulated and developed low cost weaning foods, health foods, nutritious sattu and paustik atta, protein and mineral rich biscuits.

- Documented traditional foods based on cereals and pulses in tribal areas of MP and suggested for their nutritional improvements.

- Developed and evaluated many nutritional enrich products based on minor millets such as traditional foods, fermented foods, baked foods, therapeutic foods etc.

- Developed technology for liquefaction of fruit pulps of mango, guava, papaya, banana etc. for production of clarified juices.

Innovation and best practices :

Development of Locally Adoptable Cooking Recipes Using Soybean

Training Programmes imparted to farm woman and extension workers were found to be effective in creating awareness regarding health benefits of soybean. Primary assessment of feedback received showed that there was significant improvement in the knowledge regarding the processing and utilization of soybean and its products. Respondents started using soybean for food use mainly for roti making besides soy nuts and cookies at the level of 20-30 % in their daily diet.

Education for sustainable development focusing on school lunch with adopting traditional crops in M.P.

The study was conducted in two district of M.P. such as Dindori and Jabalpur From each district 25 schools were selected for collection of information regarding mid day meal programme. Landraces samples of Kodo and Kutki were also collected for quality parameters and developed novel food products for school children. Various developed products (puffed sweet ball and malted health drink) were assessed for their acceptability using hedonic scale. Malted drink of Kodo millet and sweet ball of puffed Kutki millet were found to be more acceptable by the students and teachers from Jabalpur where as malted drink and sweet ball of puffed Kutki millet were found to be more acceptable by teachers and students form Dindori district.

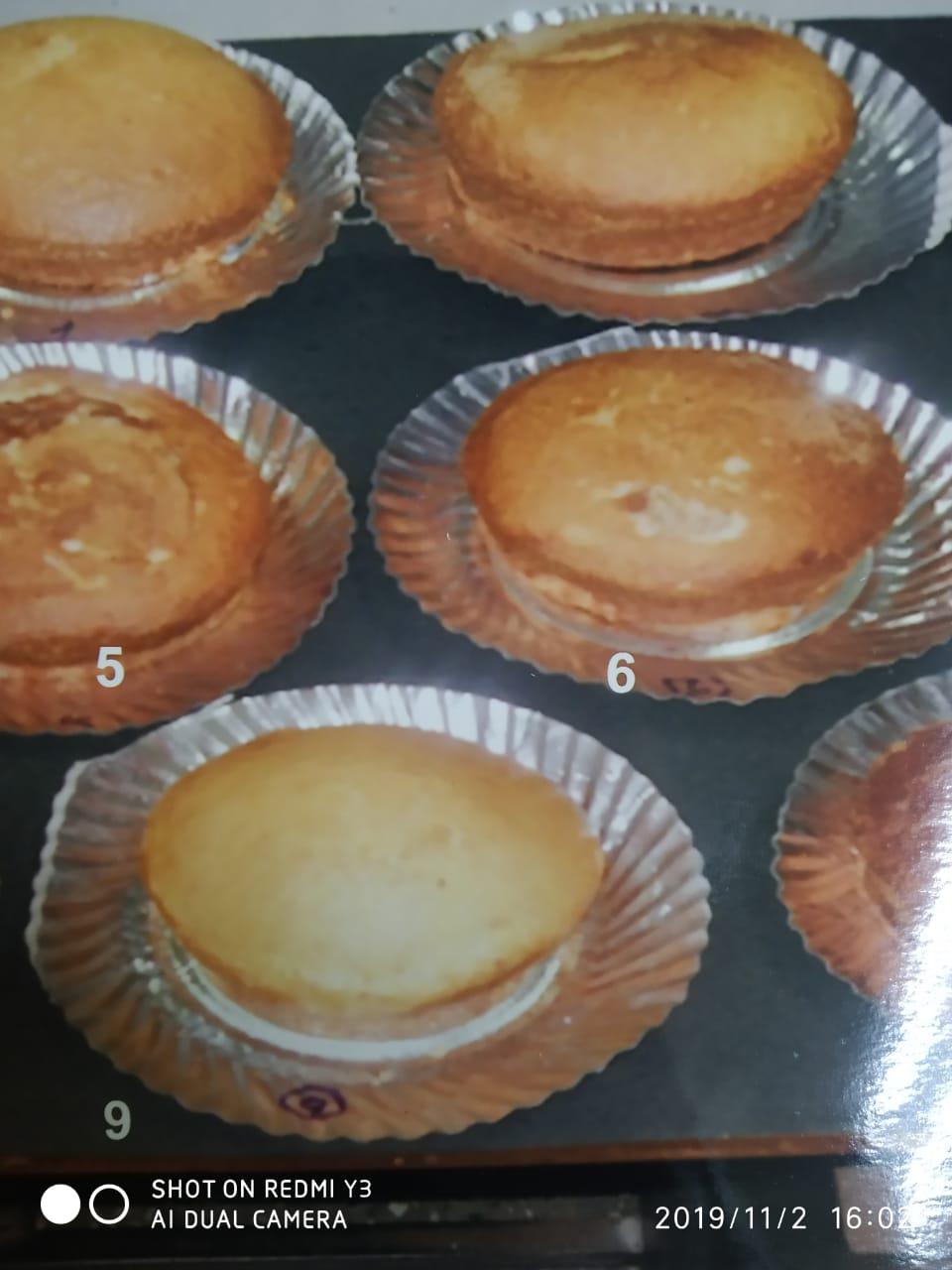

Technology for production of nutri- rich bakery and confectionary products

Pomegranate juice fortified cake was prepared with pomegranate aril, wheat flour and other baking ingredients. In the process 80% pomegranate juice fortification were standardized.

Therapeutic multigrain cookies were prepared with highly nutritive value for malnourished children and health conscious people.

|

|

|

Pomegranate Juice Fortified Cake

|

Multigrain Cookies

|

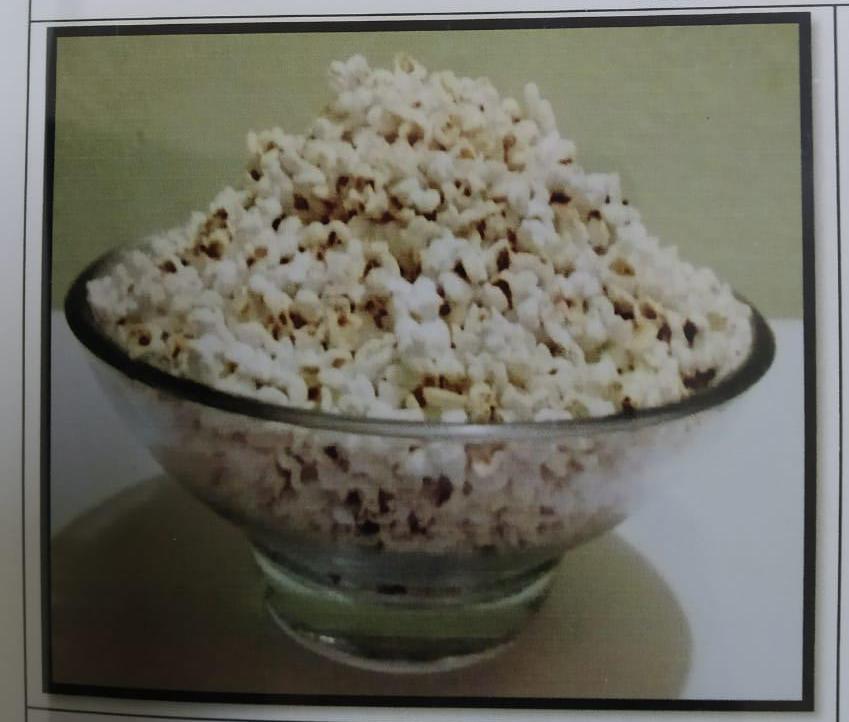

Processing and value addition of small millets (kodo, kutki, sawan and ragi)

Kodo were puffed with 2% salt solution at 2300C and 90% moisture level by microwave oven method.

Millet based instant dosa mix were prepared at 30% rice, 40% little millet 20% black gram and 10% lentil flour as best formulation whereas millet based dhokla mix were best formulated at 50% besan, 40% kodo and 10% lentil.

The instant chakli were prepared with rice flour of 20%, black gram of 20 % small millet flour 40 % and pulse flour 20 %, which were found rich in protein and highly energetic snacks.

|

|

|

Puffed Kodo

|

Kodo Fortfied Dhokla

|

|

|

|

Kutki Fortfied Dosa

|

Kutki Fortfied Chakli

|

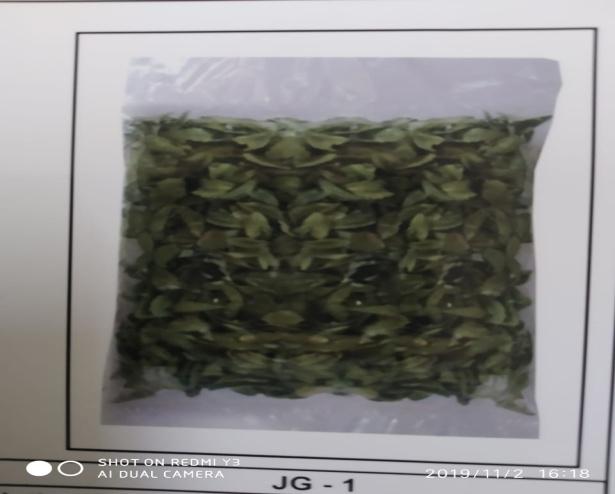

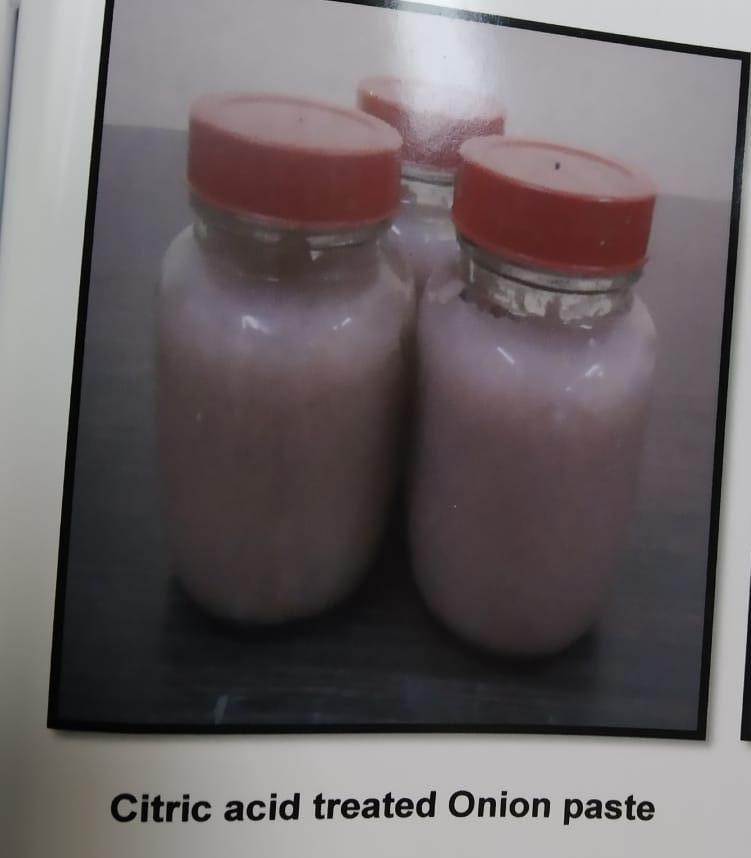

Development of value added products from vegetables

Solar dried bitter gourd chips were found best for storage period of 90 days in comparison to sun dried chips which were blanched for 96 0C for 3 min and dipped in KMS solution of 0.2 % for 5 min.

Vacuum dehydrated chickpea leaves (Variety JG-12) were found best at storage of 90 days

Low cost onion paste was prepared for minimizing the post harvest losses of onion bulb. It can be stored in glass containers up to 60 days under refrigeration condition with control microbial activity.

|

|

|

Dried Bitter Gourd Chips

|

Solar Dried Chickpea Leaves

|

|

|

|

Onion Paste

|

|

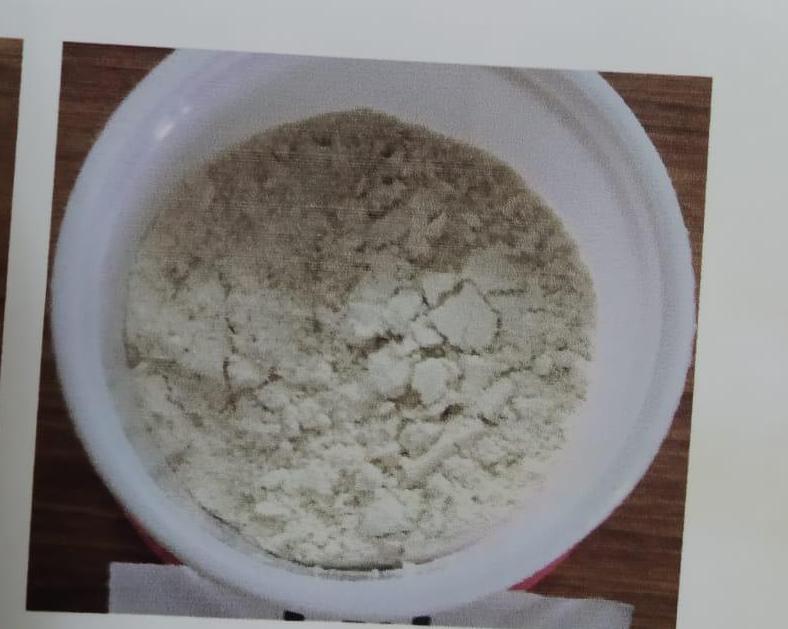

Production of spray dried malted milk powder from ragi and kodo

Malted ragi milk powder was prepared by spray drying process from 20% ragi malt slurry concentration of 20%. For this process dry temperature of 205 0C and air pressure of 3.5 kg/cm2 were optimized.

|

|

Malted Ragi Milk Powder

|

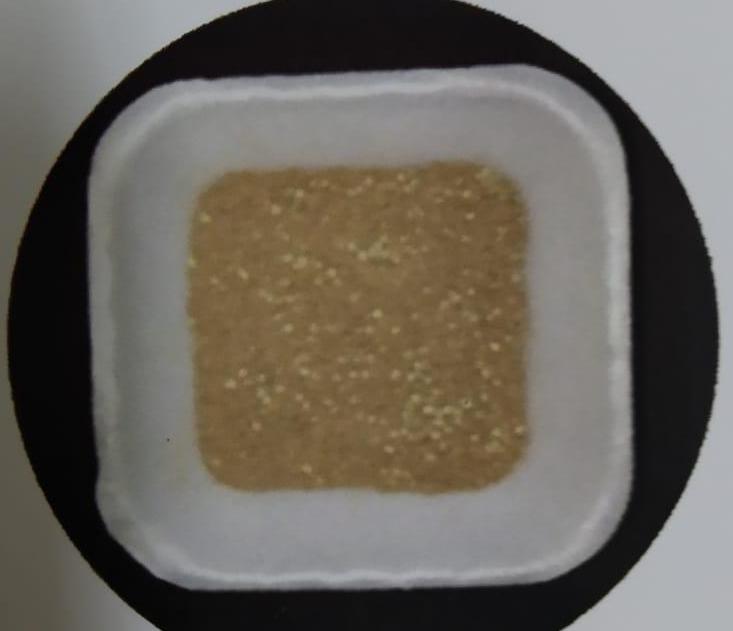

Development of instant mixes using nutraceuticals (moringa and small millets)

Geriatric food mixes were prepared from 50% quinoa with 20 % amaranth and green gram 30 % whereas moringa based geriatric food mixes were prepared from 15% moringa powder with 20 % amaranth and green gram 65 %. Prepared instant mixes were stored in polyethylene and laminated aluminium pouches up to 3 months without any deterioration at ambient condition.

|

|

|

Quinoa based Geriatric Food Mixes

|

Moringa based Geriatric Food Mixes

|

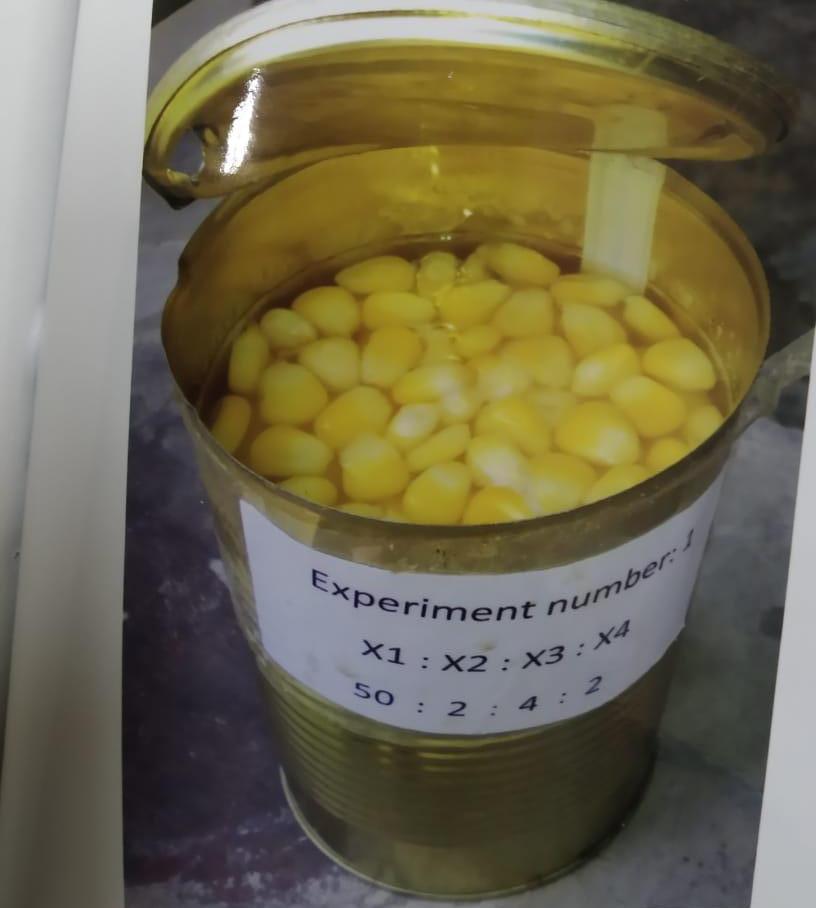

Technology for canning of baby corn and sweet corn

The best quality of canned baby corn product were prepared at canning variables i.e. holding time of 50 min , brine concentration of 2%, sugar concentration of 4 % and blanching time of 2 min.

|

|

|

Canned Baby Corn

|

Canned Sweet Corn

|