Ongoing Research Projects

AICRP on Post Harvest Technology

Mandate

- Determination of drying characteristics of the different grains, studies on existing

drying methods and design and development of various types and sizes of dryers for

on farm and commercial use.

- Packaging, handling and transporting techniques, studies on grain losses, development

of machinery and systems for better efficient handling and transportation.

- Conventional storage methods and devices and their draw backs and development of

modern structures, ventilation, space optimization and other aspects. Design and

development of new storage structures.

- Development of transitory and temporary storage and drying arrangements in framing

areas to reduce losses at the harvest time from unexpected rains and drying facilities

at grain mandies and rail heads.

- Determination of reasons for the existing poor out- turn in the processing and milling

of different grains and devising ways and means of increasing the milling yield

and reducing the losses.

- To obtain, install and conduct performance evaluation tests of indigenous as well

as promising imported prototypes of processing equipment for adoption and popularization

in the country. Also, design and development of new packaging material.

- Work on utilization of agricultural waste in different areas and evolving ways and

means of converting them in to useful products or utilizing as packaging material.

- Investigations on post harvest practices to improve post harvest processing qualities

and milling performance and reduce losses. Study of losses under different storage

conditions and find ways and means of reducing losses in storage entomology.

- Peeling, shelling and drying of fruits vegetables. Popularization of post harvest

technology in the villages in the vicinity of Jabalpur by the developing Agro Processing

Center.

Machines Developed

Power Operated Pea Peeling Machine

|

Advantage

|

Saves Labour

|

|

|

Cost

|

Rs. 35,000/-

|

|

|

Efficiency

|

98%

|

|

Labour Required

|

1

|

|

Cost of processing (Rs./h)

|

40/-

|

|

Capacity (Kg/h)

|

60

|

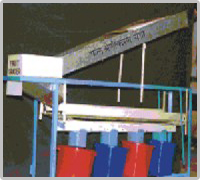

Multi Fruit Grader

|

Advantage

|

Saves Labour

|

|

|

Cost

|

Rs. 18,000.00

|

|

|

Efficiency

|

90-95%

|

|

Labour Required

|

1

|

|

Cost of processing (Rs./h)

|

40/-

|

|

Suitability for crops/ commodities

|

Spherical shaped fruits

|

|

Capacity (Kg/h)

|

1200

|

Green Bengal Gram Pod Stripping Machine:

|

Advantage

|

Saves Labour

|

|

|

Cost

|

Rs. 40,000.00

|

|

|

Efficiency

|

98%

|

|

Labour Required

|

1

|

|

Cost of processing (Rs./h)

|

40/-

|

|

Suitability for crops/ commodities

|

Green peas

|

|

Capacity (Kg/h)

|

60

|

Manual Water Chest Nut Decorticator:

|

Advantage

|

Saves Labour

|

|

|

Cost

|

Rs. 4,000.00

|

|

|

Efficiency

|

99%

|

|

Labour Required

|

1

|

|

Cost of processing (Rs./h)

|

40/-

|

|

Suitability for crops/ commodities

|

Water chestnut

|

|

Capacity (Kg/h)

|

60

|

Groundnut Testa Remover

|

Advantage

|

Saves Labour

|

|

|

Cost

|

Rs. 80,000.00

|

|

|

Efficiency

|

85 %

|

|

Labour Required

|

1

|

|

Cost of processing (Rs./h)

|

60/-

|

|

Suitability for crops/ commodities

|

Groundnut

|

|

Capacity (Kg/h)

|

40

|

Product Development

Nutritious Dalia:

The nutritious mixed porridge with wheat and soybean as ingredients in 85:15 proportions

was developed to address the problems the malnutrition. The porridge having 8% moisture

content (wb), packed in polypropylene bags was safe for 3 months storage under ambient

storage condition. The developed porridge contains 16% protein, 66% carbohydrate,

4% crude fat, 2% total ash and it can provide 1298 kcal energy. It was accepted

by the sensory panel. The nutritious dalia may be utilized for feeding babies as

weaning food.